Digital Tools

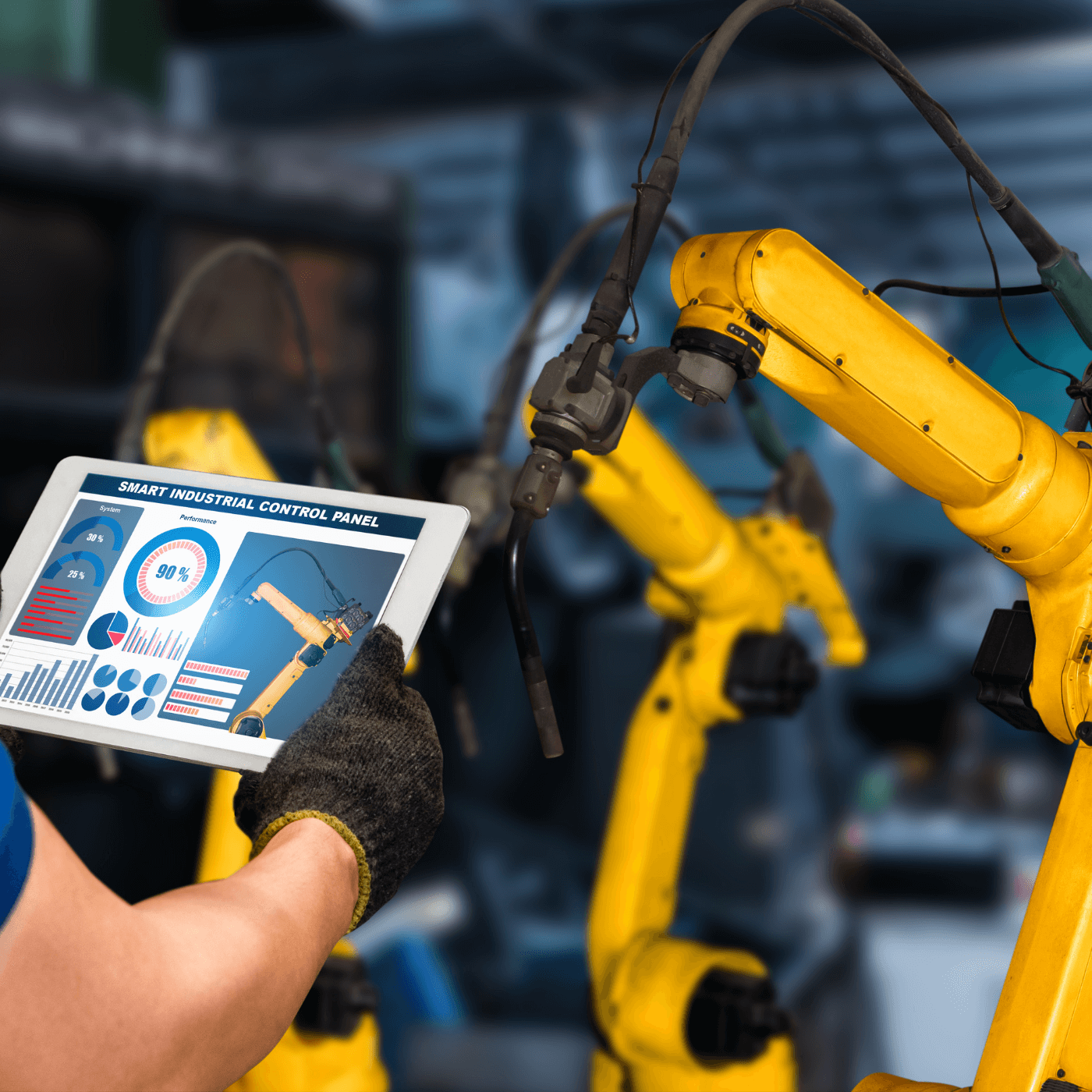

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to the use of Internet connectivity to enable objects in industrial processes to communicate with each other and exchange data. Created by integrating smart technologies into traditional industrial systems, IIoT is used in many industries such as manufacturing, transportation, energy, healthcare, and agriculture.

Value Stream Mapping

Value Stream Mapping (VSM) is a management method that visualizes the value-adding and non-value-adding steps in the processes from the supply stage of a product or service to its delivery to the end user. This method aims to increase the competitiveness of the business by identifying wastes (muda) in the processes and enhancing efficiency.

3D Printer

3D printers are devices that transform digitally created three-dimensional models into physical objects layer by layer. This process is carried out by combining the digital 3D model created using computer-aided design (CAD) software with a specific material used in the 3D printer, layer by layer.

The Contribution of Quality System to Efficiency in Production

Efficiency in production processes holds significant importance from raw materials to end-users. Quality systems assist businesses in effectively managing these processes, minimizing losses, and enhancing operational efficiency. Quality systems not only help businesses reduce costs but also mitigate environmental impacts.

Artifical Neural Networks

Artificial Neural Networks are models used in computer science and artificial intelligence that are designed to mimic the functionality of biological neural networks. These artificial neural networks consist of interconnected artificial neurons that receive input data, process it through layers of neurons, and produce output.

Importance of MES and APS Systems

Manufacturing Execution Systems , (MES) and Advanced Planning and Scheduling , (APS) systems are essential tools for modern manufacturing plants. While each system offers specific advantages on its own, the combination of these systems leads to significant improvements in production efficiency, product quality and overall operational effectiveness.

The Impact of Quality Measurement in Manufacturing Enterprises

The costs of poor quality not only lead to wasted resources for businesses, but also affect national economic resources. These costs come in various forms, such as material waste, process failures (e.g. idle machine work, energy consumption and labor costs). On an annualized basis, these losses can be substantial. In addition, for businesses supplying consumers or large industries, the costs associated with returns and complaints leading to reputational damage and product losses should not be underestimated.

The Effect of Cycle Time Analysis on Industrial Performance in MES Systems

Today, industrial enterprises need to continuously optimize their production processes in order to increase productivity and gain competitive advantage. In this context, Manufacturing Execution Systems , (MES) have a critical importance. MES offers significant advantages such as increasing productivity and reducing costs by providing real-time monitoring and management of production processes. Cycle time analysis, one of the key components of these systems, is an important element that directly affects the performance of production processes.

What is Industry 4.0? What Does Industry 4.0 Mean?

Industry 4.0 represents the final stage of the digital transformation in industrial production. This concept is characterized by the widespread use of digital technologies and intelligent systems in industrial processes. Industry 4.0 includes the integration of the Internet of Things (IoT), artificial intelligence (AI), big data analytics, cloud computing, automation, robotics and other advanced technologies.

What is the difference between MES & MOM?

MOM (Manufacturing Operations Management) is an approach or set of software and systems used to optimize the process of planning, monitoring and controlling manufacturing processes. Basically, it aims to make an organization's manufacturing processes more efficient, effective and flexible. MOM systems are usually designed and used to cover an entire production facility.

What is MOM? MOM System

MOM (Manufacturing Operations Management) is an approach or set of software and systems used to optimize the process of planning, monitoring and controlling manufacturing processes. Basically, it aims to make an organization's manufacturing processes more efficient, effective and flexible. MOM systems are usually designed and used to cover an entire production facility.

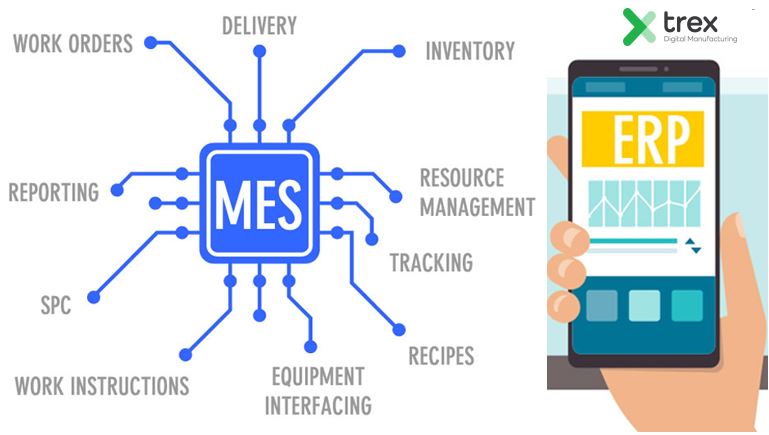

What is MES? MES Systems

MES (Manufacturing Execution System) is a type of information system used to monitor, manage and optimize production processes in a manufacturing enterprise. Basically, it is a type of software or system that manages the manufacturing operations that take place in factories or production facilities.

What is Cloud Computing? What are the Benefits?

Today, it has become an inevitable necessity for businesses to use technology effectively in order to maintain their competitiveness and adapt to rapidly changing market conditions. At this point, cloud computing stands out as a flexible, reliable and efficient technology that responds to the needs of the age. Cloud computing enables businesses to improve their information technology infrastructure, optimize business processes and offer innovative solutions.

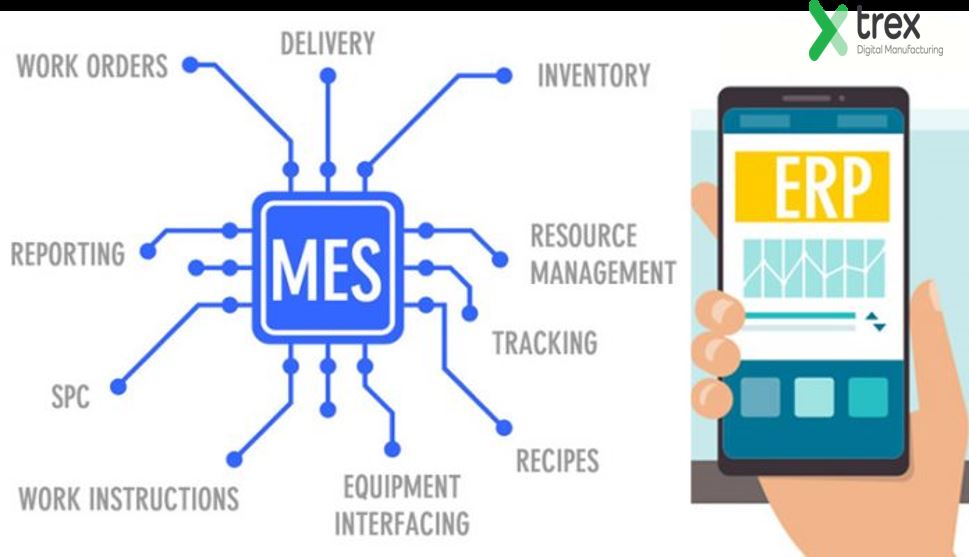

ERP Integration in MES Systems

ERP, or Enterprise Resource Planning in Turkish, has become indispensable for the majority of businesses today. Thanks to ERP, many departments such as production planning, supply chain, human resources, customer relations, financial management can be used as integrated systems. These top systems are managed with ERP software that the employees of the organization can now use easily from their computers and are familiar with.

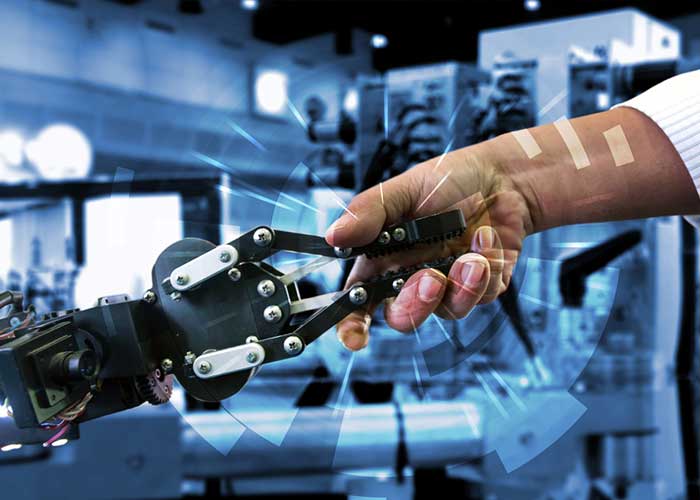

What is RPA? Robotic Process Automation (RPA)

Robotic Process Automation (RPA) The age of automation with AI and robotics Recent advances in digitalization have had a significant impact on the work performed by employees, as well as on products and their associated technologies. It is predicted that in the near future a significant amount of the work that is routinely done will be automated or robotic. RPA is absolutely essential for the available workforce to focus on more value-added tasks than routine work and for the company to generate more value.

Smart Factories with DCAS Live Mobile Application

From the past to the present, information is the most valuable phenomenon. The regular storage of information with the development of computers and the rapid spread of information with the development of the internet have brought a new dimension to information.

Machine Learning, Deep Learning and Predictive Maintenance in MES Systems

In manufacturing, as in many other areas of life, technology has long played a leading role in setting trends - quite normally. However, for some time now, this leading role has been focused on software technologies. Recent concepts such as Cloud, Big Data, Data Mining, Internet of Things, Augmented Reality and finally Industry 4.0 are all trend structures and terms built on software technologies. The latest trend has entered our lives in three blocks; Artificial Intelligence, Machine Learning and Deep Learning.

Selection, Installation and Return on Investment (ROI) of MES Systems

Today, customer expectations include high quality standards as well as price advantages. Manufacturers have to keep up with these high standards and target prices.

Therefore, today's manufacturers have to produce at high standards and do so by reducing their costs. At this point, there is a search for a way out. As a result of this search, manufacturers who realize their problems in the production area, conduct research to overcome this problem, create their options and determine the method, realize that they need the MES System.

ERP Integration in MES Systems

When integration is mentioned, only ERP integration should not be considered. It can be integrated with all 3rd party software such as predictive maintenance software used in planning, quality, workflow management, production area. It should be. MES-ERP integration is very important. This integration is very important for the success of your ERP system in use. As it is known, ERP success rates are around 40%. The reason why it is so low is clearly shown below;

Machine Equipment Communication in MES Systems

The age, brand and capabilities of the machinery and equipment to be included in the MES System are not technically important. The only importance may be the limitation of the data to be received. For example, all technical data on a 30-year-old machine can be obtained through additional sensors or by using relays to bring the signal to the desired level.

Customization in MES Systems

Customizations play an active role in the acceptance of the program by the operators, who are the most important people for collecting data from the field. We can define the coming together of two different systems that do not know each other as a tissue harmony. One of the systems here can be defined as MES Systems and the other as the established production culture of the factory. Without changing the established culture of the factory, factories should be implemented with customizations that will make their work easier, on the contrary, without creating additional burden on people.

Visual Smart Factories with MES Systems

The systemic approach that enables automation systems to move to the next stage can be characterized as the Smart Factory.

It can be characterized as a set of systemic approaches covering production, social business network, integrated product development, data-driven control, supply chain management, digital factory logistics, cloud services, factory design in a digital environment.

Push Notification Management and Importance in MES Systems

Today, fast access to information has become almost as important as information itself. Access to information at home, at work, on the street, anywhere you can think of has started a new era. Smartphones, the most popular technologies of today, are a tool for us to access this information quickly. The importance of push notifications that notify the user about the types of events happening on the machine is increasing day by day. This is because there is a rapid evolution from technologies that notify the user via vibration when an e-mail arrives to push notifications on smart TVs and even wearable technologies.

Reporting and Analysis Techniques in MES Systems

Every meaningful data in the production area can be recorded. The requirements are determined within the conceptual scope.

Classically, your performance, quality, availability values, which are sub-parameters of your productivity in MES Systems. Your planned or unplanned maintenance times and all maintenance data for your MTTR-MTBF values, which are important KPIs.

Machine Equipment Planning in MES Systems

The work plan links a sequence of operations and machines. This sequence may also contain alternate stations and conditional loops. The actual path of the production unit (selected alternative station) is not determined until the finest planning stage of the order. The work plan is defined for each product and also applies to its variants. There can be raw materials or pre-products. Internally produced pre-products are also mapped in the MES.

Mold Life Tracking in MES Systems

The basis of industrialization is the production of products in accordance with standards within certain tolerances and the seamless interchangeability of these products.

Scientific research is carried out to produce these products quickly and economically, and the results obtained are used in the emergence of new production techniques or in the development of existing ones. Molding, which can be defined as the creation of a product by compressing liquid or solid raw material in a geometry with certain shapes and dimensions, is used as the most suitable method for the rapid and economical production of many products with the desired properties.

Work Order Management in MES Systems

We can define a work order as a process commonly used by manufacturing businesses.

If we need to talk about it in a little more detail, it includes the tasks assigned to the personnel working in production, including the routes and product recipes of sub-operations. For example, each line in the factory may be producing a different product or each operator may be working to produce a different product. A work order, on the other hand, provides precise information such as which line or which operator should produce what at that moment and how many units should be produced.

Lot Tracking, Traceability and Barcode Applications in MES Systems

The ability of barcodes to carry complete information about products has increased the necessity of their presence in enterprises. They help the production process at every stage, starting from the determination of the components needed at every stage of production, i.e. inventory, finished goods.

Quality Management Applications in MES Systems

Since we will talk about Quality management processes under MES systems today, it would be more accurate to mention the importance of Quality management only in the production sector.

First of all, what is Quality? It is necessary to look at the answer to this, in fact, although there is no clear definition of quality, with the generally accepted definition of Quality: It means that the specified function and all measurable properties of a product or service are and will always be the same.

Maintenance Management Applications in MES Systems

TPM stands for Total Productivity Maintenance.

TPM is a maintenance management approach that envisages autonomous maintenance with the participation of all employees in production and service processes, adopts a prevention approach rather than troubleshooting, and maximizes machine and equipment efficiency.

Validation Applications in MES Systems

Validation; It covers the procedures that need to be done to prove that the method used is accurate and precise and that it continuously performs what is expected. In other words, it is ensured that a planned production is continuously checked whether it is realized within the plan.

When working with a validated method, it is guaranteed that the process is precise, accurate, specific, consistent, valid and reliable.

The Impact of MES Use on Competition

In these days when we are adapting to Industry 4.0 applications and talking about Industry 5.0 innovations, the importance and necessity of Intelligent Manufacturing Systems, (MES) are increasing day by day. The Internet of Things (IoT), artificial intelligence, machine learning, which have entered our lives with Industry 4.0 and have an important place, are carried to another dimension with Industry 5.0.

ERP Integration in MES Systems

ERP, or Enterprise Resource Planning in Turkish, has become indispensable for the majority of businesses today. Thanks to ERP, many departments such as production planning, supply chain, human resources, customer relations, financial management can be used as integrated systems. These top systems are managed with ERP software that the employees of the organization can now use easily from their computers and are familiar with.

Production Management Systems - Industry 4.0 Benefits

Production Management Systems and Industry 4.0 have become two inseparable parts in the industrial era. With the developing technology, factories have reached a level where every moment of smarter production can be monitored.

Whether it is medium-sized factories or huge production sites, they all have production systems in their structure. But the important thing is to question how healthy, how efficient a production system is and its traceability. Industry 4.0 technology helps us at this point.

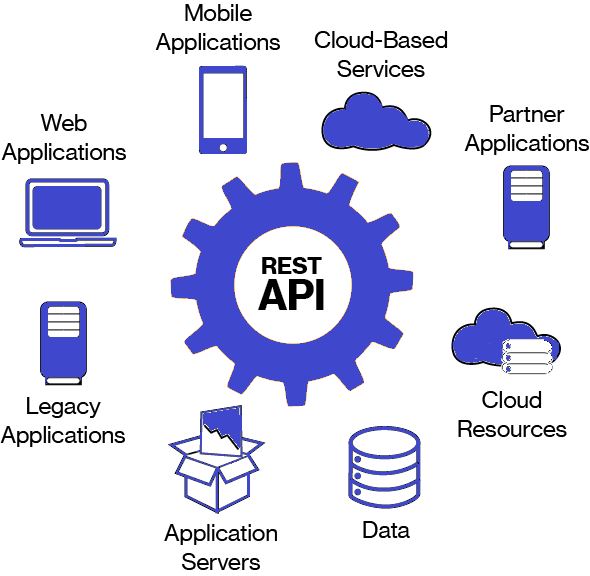

RESTful Web Services

Software systems used today have to communicate with each other and perform various data transfers between them due to many requirements. The increase in distributed systems and the need for integrations between systems has created the concept of "Web Service" and led to its development. In short, Web Services represent protocols/rules that enable different software systems to talk to each other and the software that provides these protocols/rules are called web service software.

Advantages of Cloud Technologies for Businesses

Both in the world and in our country, it is unthinkable for businesses to be competitive in their sectors without using information technologies. In order to comply with global competitive conditions such as low cost, efficiency, service in a wide geography, flexibility and speed, all today's businesses, whether small or large, invest in information technologies at the rate of their budgets and aim to use these technologies in the most efficient way.

Choosing the Right MES Application

The primary objective of production organizations is to find the most economical way to produce. They must be able to survive in the face of competition that changes faster than they do. No matter how perfect organizations are, the only way to achieve time, cost and quality targets is to continuously improve their systems.

Magical Intelligence 4.0

It addresses the possibilities that technological developments such as Industry 4.0 and artificial intelligence bring to humanity. Artificial intelligence, especially machine learning and deep learning, can make predictions, identify patterns and optimize processes using large data sets. This is done by aggregating and analyzing data that can be used by both small and large companies. These technological advances offer solutions that humanity has never seen possible before and make business processes more efficient.

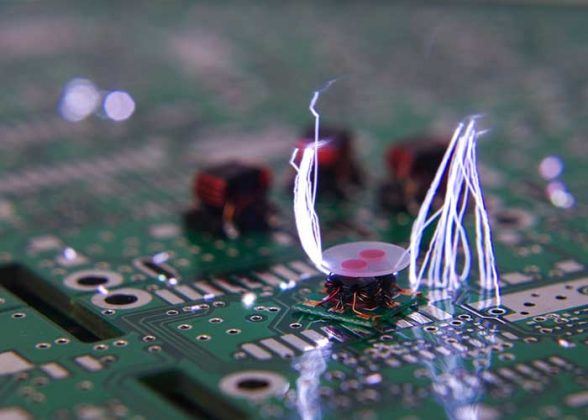

ESD (Electrostatic Discharge)

There are some precautions to be taken before starting to repair an electronic card.

The problem that reveals these precautions to be taken is ESD, that is, ELECTROSTATIC DISCHARGE, as described in the title of the subject, is the static charge generated by friction with low current and high voltage in the human body.

Using Field Data Collection for Improvement Activities

In today's market conditions, competition is increasing and new actors are entering the market. In addition, daily changes in the markets lead to increased uncertainty. Therefore, the importance of speed and cost reduction in production processes and other management processes is increasing. In order to speed up processes and reduce costs, the primary requirement is to quickly collect the right data from the field, analyze it, find losses and take measures to improve them. By monitoring the effectiveness of the measures taken and taking new measures, if necessary, to reduce the impact of losses on costs. It is also one of the most important issues to make this a business culture and a daily way of life for the whole team.

OPC Technology in Manufacturing Execution Systems

Production Tracking Systems; In your business, the existing lines, stations, in short, the entire production process, all operational data you have received from the past to the present, finished projects can be monitored retrospectively, as well as instant production allows you to monitor and intervene live.

The Importance of Grounding

Welding machines, spot welding machines, robots and asynchronous motor drives, which are increasingly used in industry today, cause voltage oscillations to metal bodies with the harmonige in the power lines and the magnetic field they emit, which once again reveals the importance of grounding. As a result, electronic cards operating with low voltage are affected and do not work stably.

Technical Support Behind MES Solutions

Manufacturing Execution System MES , (Manufacturing Execution System), in short, is an instant online monitoring system of the processes from A to Z of production in your factories. In this system, apart from the human factor, machinery and the tools used are more important. The biggest role in the process of rapid adaptation of Industry 4.0 to factories lies under Mes solutions.

The Impact of Digital Transformation on Corporate Growth and Development

The Impact of Digital Transformation on Corporate Growth and Development

Digital transformation is a concept that defines the process of developing and changing workflows and culture in order to find solutions to social and sectoral needs with the integration of digital technologies. Digitalization, which focuses on creativity and innovation, has emerged to achieve more efficient results than traditional methods.

Barcode Usage in ERP Businesses

The ability of barcodes to carry complete information about products has increased the necessity of their presence in enterprises. They help the production process at every stage, starting from the determination of the components needed at every stage of production, i.e. inventory, finished goods.

What is Cryptology?

Cryptography is derived from the Greek "kriptos" meaning secret and "graphi" meaning writing. Cryptology is the science of ciphers. Cryptology is a mathematical science and is usually based on number theory. The process of converting a text or text into a meaningless form according to a key (rule) in order to prevent it from being read by unwanted parties is called encryption.

The Importance of Competence in MES

In today's world, where digitalization transcends industry and industry and consolidates its place in every aspect of our lives, you need partners who know what they are doing, who know what they are doing, who know what they are doing and who will share their past experiences with you in your development and transformation moves.

Why MES , (Manufacturing Execution Systems)?

With each passing day, the qualities of industrial products, the purchasing power of the customers of the product increase, and their demands from them increase and/or change as a result of the diversification of their processes¹. It is as important to understand and implement these changes correctly as it is to take action as early as possible.

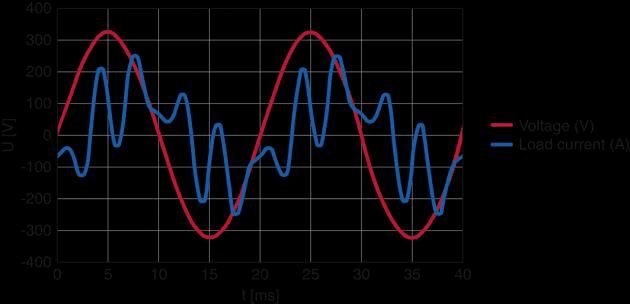

Shielding in Network and Signal Cables

All the electrical appliances, sound systems, robots, motors that we use in our daily lives and industrial systems create an electromagnetic field around them during their operation. This effect, called EMI, causes distortions on the signals passing over the cables, communication breaks and many other effects.

Global Competitiveness Index 4.0

The World Economic Forum (WEF) conducted a global competitiveness index study. Within this framework, WEF, as the organization that has been setting the benchmarks of long-term global competitiveness for 40 years, aims to be a compass for economic administrations when announcing the new "GLOBAL COMPETITIVENESS INDEX 4.0". Within the 12 pillars (institutions, infrastructure, ICT adaptation, macroeconomic stability, health, skills, product market, labor market, financial system, market size, labor market dynamism and innovation capacity), fundamental development problems such as the functioning of institutions continue to pose obstacles to global competition.

Systems Feeding ERP

ERP systems can manage the entire information flow of a business, but sometimes they also need 3rd party software.

You may want to get very detailed information from information sources such as production, human resources, CRM, trade portal of an enterprise. You can also achieve this with ERP. However, you may not want to exhaust the database of ERP with very dense information coming from the lowest level. By information intensive I mean processes that generate over a million records in an hour.

Production Data Acquisition Systems

The Production Data Acquisition System enables the recording and reporting of the production process through touch screens integrated with the machines on the shop floor. This system is based on the logic of counting the products produced and stops are recorded manually or pre-planned. OEE values are calculated with the data from the machine and reports are generated. Touch screens increase productivity by engaging operators.

IOT and IIOT EVERYWHERE!

IOT (Internet of Things), the Internet of Things, is simply the name given to all objects that computers can access. IIOT (Industrial Internet of Things), on the other hand, takes the concept of IOT a notch higher and describes all the technologies that computers talk about in industry.

Reporting and Analysis Techniques in Manufacturing Execution Systems , (MES)

At the beginning of the last century, it was not very difficult for businesses to increase their sales. Due to the low number of factories and consequently low competition, the products produced found buyers even if their prices were high. Therefore, in such an environment, companies were far from concepts such as R&D, Innovation and Information Systems.

Who Should Be Asked When Buying ERP?

The company, which thinks that it has established processes, starts to think that it cannot follow its business as it wants in the existing program and that the reports are insufficient in directing the functioning of the company. At this point, it is decided which ERP should be the new ERP by taking the opinions of certain people from outside and inside.

What is Big Data?

The amount of information processed by computer networks every day is measured in terabytes and petabytes. At our current rate, we are thought to be generating 2.5 quintillion bytes of data every day, and this number is growing every day. This pace is accelerating with the growth of the Internet of Things (IoT). When the statistical data of the devices connected to the Internet of Things (IoT) around the world are analyzed, an exponential growth is predicted.

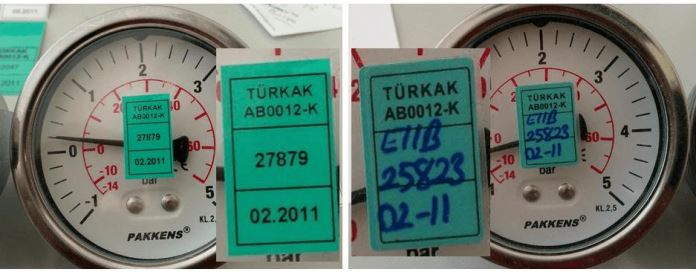

Calibration of Test Measuring Instruments

Calibration, which determines the accuracy of measuring instruments with reference measurement standards of known accuracy and detects deviations, is vital for every business. Companies that act with calibration awareness increase product and production quality while ensuring compliance with international standards.

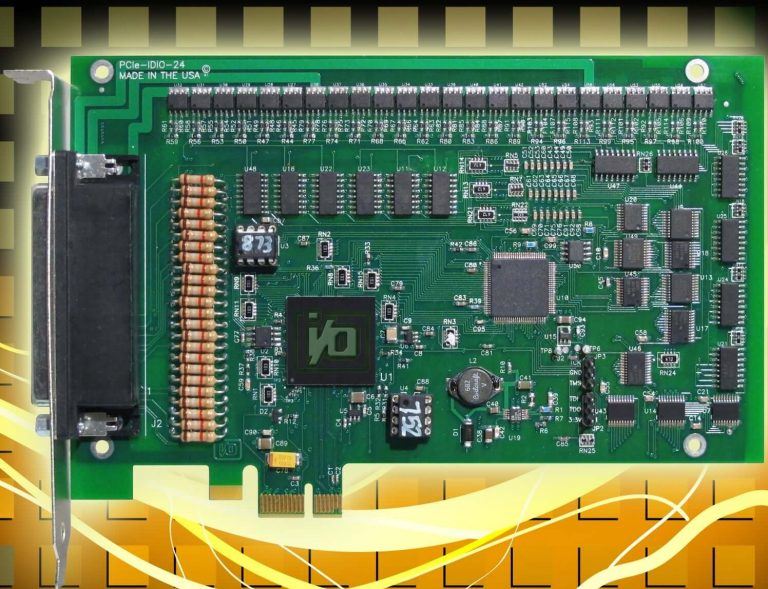

Industrial IO Cards

"I/O cards used in industry play an important role in the control of machines by performing input and output functions. They have the ability to process different signals, evaluate sensor data and control various systems. These cards, which have a wide range of applications from traffic lights to elevators, attract attention with their high performance and various technical features."

Predictive Maintenance Applications and Anomaly Detection

Among the 16 major losses taken into account in the calculation of the OEE value, which is the most important indicator of the production efficiency of the enterprises in the manufacturing industry, the most important category is the 8 major losses under the title of Equipment Effectiveness. Among these 8 losses, breakdown losses can be reduced directly and defective product losses can be reduced indirectly by predictive maintenance practices and OEE values can be improved.

3 Training - 12 Hours