Articles

A Comparative Study of Classification and Clustering Methods for Data Analysis in Digital Transformation and IoT Systems

This studyemploys classification and clustering methodologies on datasets derived from digital transformation and Internet of Things (IoT) initiatives within the cable and automotive sectors. The analytical procedures are conducted utilizing the KNIME platform, employing Support Vector Machines (SVM) and K-Means algorithms. The results indicate that SVM exhibits superior accuracy rates compared to K-Means within both industries. The data collection methodology facilitated by the Mert Software IoT platform is identified as reliable and efficacious. The primary objective of this article is to augment decision-making precision in digital transformation software and contribute to the scholarly discourse within this domain.

Turgay Tugay BİLGİN, SüleymanBurak ALTINIŞIK, Nihat Aydın ADIGÜZEL

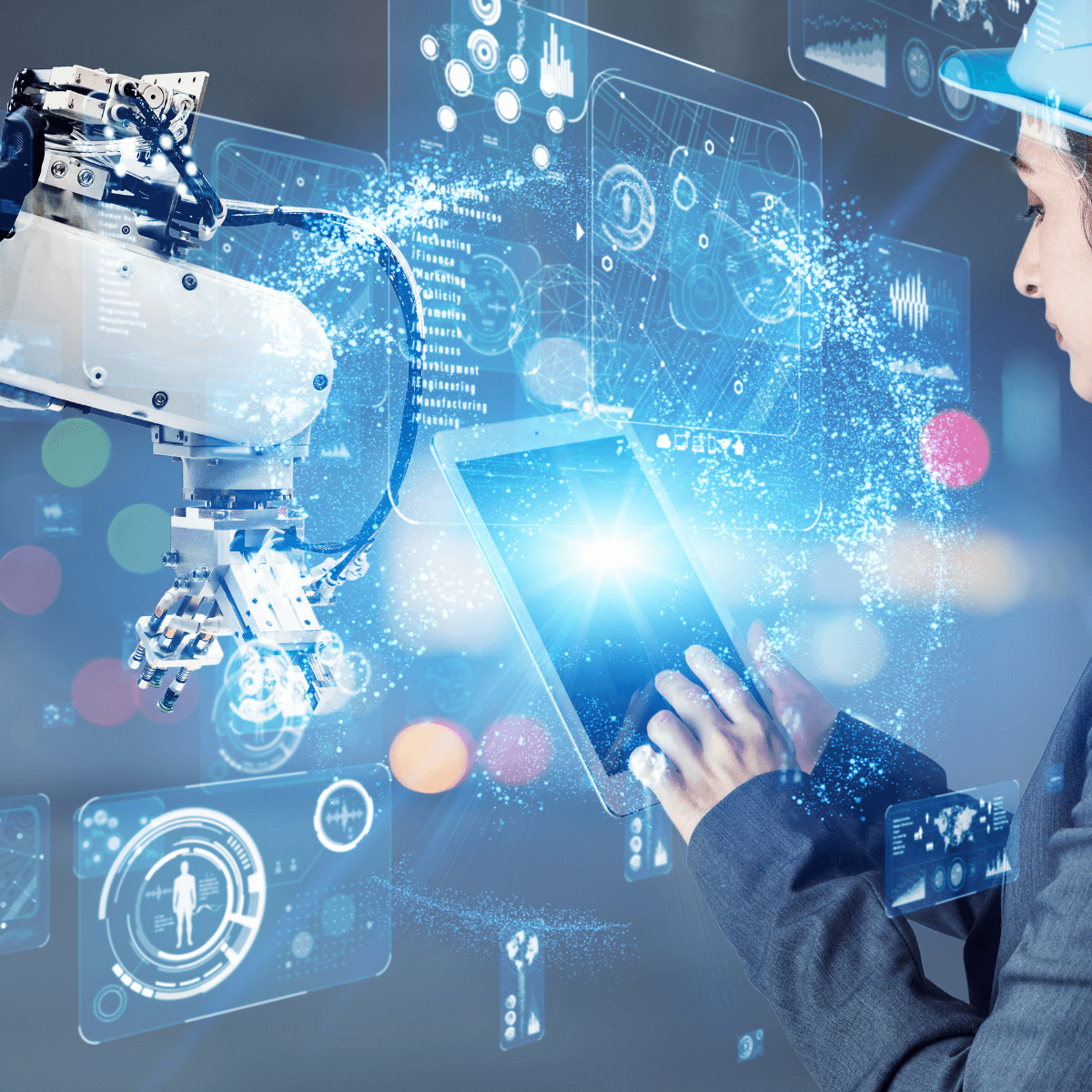

Advancing Workplace Safety: A Proactive Approach with Convolutional Neural Network for Hand Pose Estimation in Press Machine Operations

Press machine operations are integral to goods production across industries, yet worker safety faces significant risks. Machine misuse and non-compliance with safety standards contribute substantially to these incidents. This study addresses the mounting concerns regarding workplace incidents through a proactive solution—a Convolutional Neural Network (CNN) model crafted to prevent press machine misuse by monitoring workers' hand placement during operation. The model that we suggest ensures adherence to safety standards. The CNN model does not replace the role of human operators but acts as a supportive layer, providing instant feedback and intervention when deviations from safety standards are detected. In conclusion, this research endeavors to pave the way for a safer and more secure industrial environment by leveraging the capabilities of advanced technology. The proposed CNN model addresses current concerns and sets a precedent for future advancements in ensuring workplace safety across diverse industries.

Şuayip Aykut ATMACA, Hüseyin HAMAD, Burcu Çağlar GENÇOSMAN

Enhancing Energy Efficiency and Real-Time Monitoring in Industrial Environments Through an Integrated Software Solution: NIGHTWATCH

Globally, the demand for energy continues to increase due to factors such as heating, lighting, transportation and fuel supply for various appliances. In this context, achieving energy efficiency has required a comprehensive approach covering activities related to energy generation, transmission and consumption. The presented work works in industrial environments and interfaces with energy analyzers to collect and analyze data such as energy consumption, instantaneous current and voltage. This initiative aims to provide real-time visibility into energy-related operations in factory facilities. In addition, the software's capabilities extend to retrospective data analysis, providing informed insights for future forecasting. Furthermore, the integration of energy consumption data from analyzers into the Manufacturing Execution System , (MES) facilitates job-by-job energy tracking

Kader Nikbay OYLUM , Kenan SELÇUK , Turgay Tugay BİLGİN

A NEW HYBRID SOFTWARE TESTING AUTOMATION FRAMEWORK

Nowadays, with the development of software technologies in all areas of life, software testing, which is an indispensable need of the software life cycle, has become open to development and change. The replacement of manual testing of software products with test automation systems that minimise the human error margin provides the most important example of the transformation of testing processes into a dynamic structure.

Meral BOZDEMİR, Turgay Tugay BİLGİN , Kader NİKBAY OYLUM

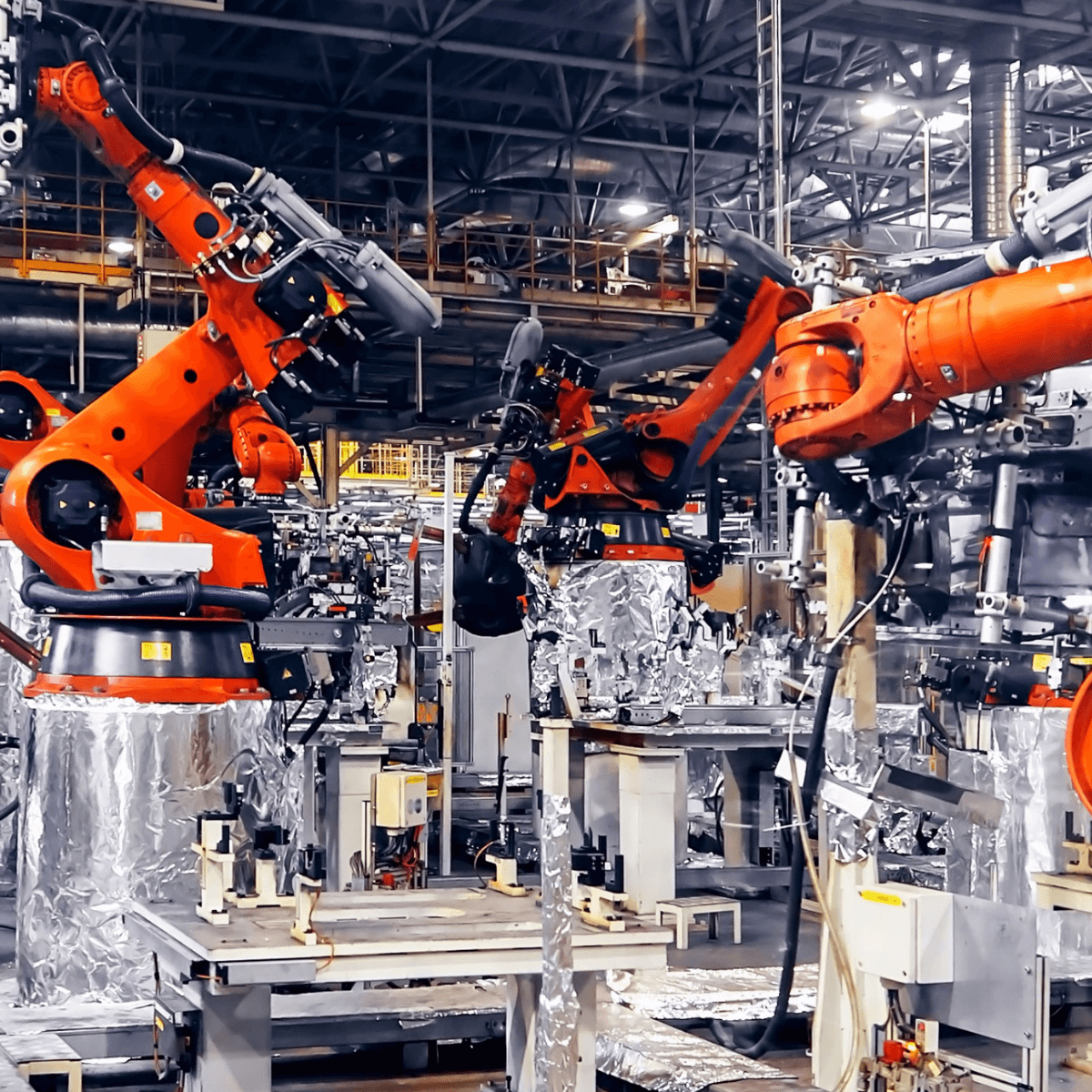

A New System Design for Making Non-Intelligent Handheld Devices Used in Production Compatible with Industry 4.0

Today, with the introduction of the Industry 4.0 concept in the literature, the process of digitalization of factories has accelerated. The basic logic of the digital factory approach is to turn the machines and equipment that make up the system into smart system elements that talk to each other. Based on the idea of smart equipment; in this study, it is aimed to smarten these hand tools by including electronic cards and software components in non-smart electric screwdrivers, to communicate with various IoT applications or cloud applications, and thus to minimize the human error margin in the work done.

Kader NİKBAY OYLUM , Turgay Tugay BİLGİN, Kenan SELÇUK